Zinc Needle Remediation

Having unexplained server hardware failures or catastrophic and permanent PDU failures in your data center or server room? You may have zinc needles or the potential for zinc needles (also known as zinc whiskers).

Having unexplained server hardware failures or catastrophic and permanent PDU failures in your data center or server room? You may have zinc needles or the potential for zinc needles (also known as zinc whiskers).

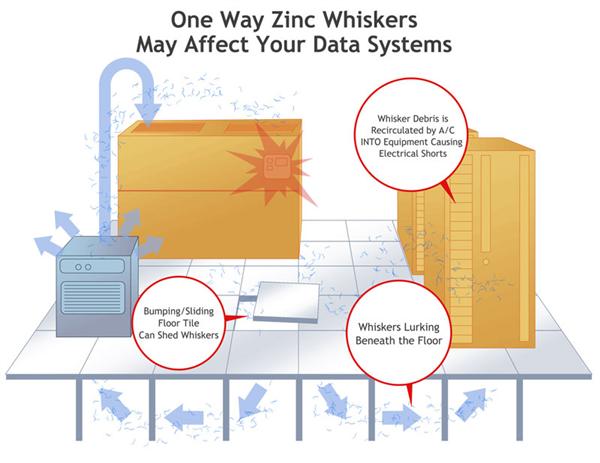

Zinc whiskers can be dislodged from the metal tracks of raised flooring, migrate via heating and air conditioning ducts into electronic equipment and cause short circuits if they settle onto circuit board surfaces. For more information on metal whiskers, visit http://nepp.nasa.gov/whisker.

Many data centers we’ve dealt with over the years had zinc needle problems. And we’ve saved these companies hundreds of thousands of dollars, sometimes millions, by using our proven and proprietary remediation process to safely eliminate the threat of zinc filaments, often without having to replace the access floor or experience downtime!

Many data centers we’ve dealt with over the years had zinc needle problems. And we’ve saved these companies hundreds of thousands of dollars, sometimes millions, by using our proven and proprietary remediation process to safely eliminate the threat of zinc filaments, often without having to replace the access floor or experience downtime!

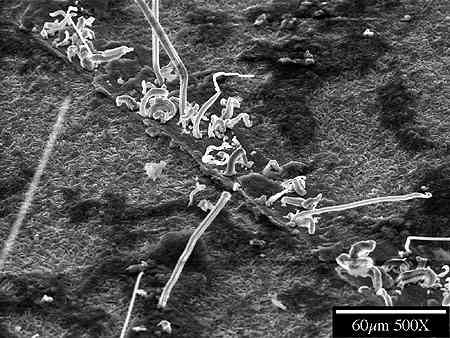

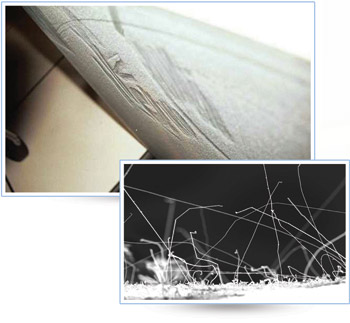

Zinc Needles are tiny conductive filaments of zinc typically less than a few millimeters (mm) long and only a few thousandths of a millimeter in diameter. They can grow from metal surfaces (e.g., steel) that have been electroplated (galvanized) with zinc for corrosion protection. The growth process consists of an unpredictable incubation period (months or perhaps even years) followed by a period of growth at rates as high as 1 mm/year. Other sources of zinc whiskers include zinc-plated floor supports/rails, computer equipment racks and hardware such as screws, nuts, washers and bus rails.

Zinc whiskers are conductive and therefore they will cause electrical shorts if they manage to bridge tightly spaced electrical conductors. Now that zinc whisker-induced shorts have been so convincingly demonstrated, some former “seemingly inexplicable” shorts are now regarded as explainable as having been caused by zinc whiskers. In recent years many computer equipment failures (servers, routers, switches, etc.) ranging from nuisance glitches to catastrophic system failures have been attributed to zinc whiskers.

Warning! Many companies in the industry claim to remediate zinc. If their process involves downtime or merely vacuuming tile undersides then your facility will be at risk! SET3 has worked with expert scientists and chemists to develop a proprietary method for remediating zinc in-place in your facility to avoid the risks of downtime or an exceptionally expensive floor or entire facility replacement cost. Call us today 800-401-6883 to see how we can help. Download our whitepapers from the sidebar on the right.

Zinc Needle Trivia

Zinc Whiskers are NOT a newly discovered phenomenon. They were first reported in the 1940s!

Excessive particulate such as zinc needles can classify your building for “Sick Air Syndrome”.

Physical Attributes (typical)

– Length: a few millimeters or less

– Diameter: a few microns (thousandths of a millimeter)

– Shapes: straight or kinked filaments, nodules

– Texture: fluted and/or striated along axis of growth

– Conductive: can carry tens of milliamperes before melting

Growth Behavior

– Mechanism of Growth: Some studies show Zinc Needles grow to relieve compressive stress within the film- however, this is unconfirmed.

– Incubation: ranges from days to years

– Growth rate: typically less than 1 mm/year

Failure Modes:

– Intermittent Shorts if available current > tens of milliamperes

– Permanent Shorts if available current < tens of milliamperes

– Metal Vapor Arcs initiated in vacuum when V > dozens of volts and I > tens of Amperes. Such arcs are capable of sustaining HUNDREDS of AMPERES

Zinc Needle Remediation

If you are experiencing unexplained power failures or computer failures – you may have zinc needle contamination. We strongly recommend lab testing to confirm zinc presence. For more information on zinc needles or for zinc needle cleaning / remediation Contact us at 1-(800) 401-6883.